Transforming Composite Part Manufacturing: Tool/Mold Design services Offered by Ahmedabad Textiles Industry’s Research Association (ATIRA)

Design in composites is paramount for tailoring material properties to meet specific performance requirements, optimizing structural integrity, and reducing weight. Composites offer unparalleled design flexibility, allowing for the creation of complex geometries that are difficult to achieve with traditional materials. Effective design can enhance damage tolerance, repairability, and environmental performance while also improving cost efficiency. By leveraging the unique characteristics of composite materials and employing innovative design techniques, engineers can create lightweight, durable, and sustainable structures for a variety of applications across industries such as aerospace, automotive, and construction.

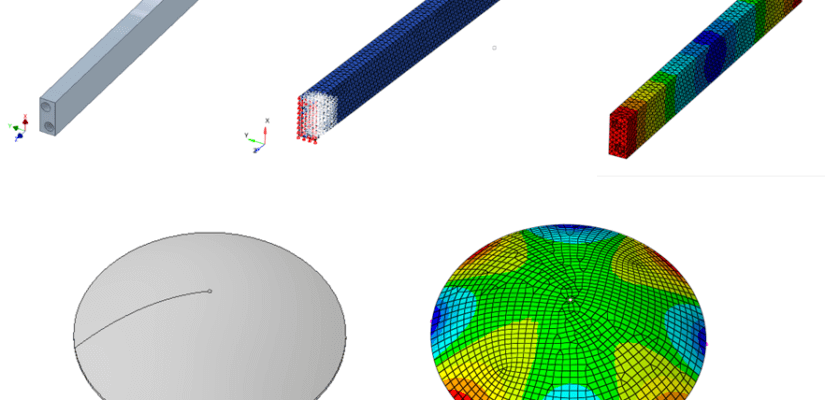

Molds/Tools are the cornerstone of any composite part manufacturing process. The quality of the final part is inherently tied to the quality of the tool used in its creation. Molds/tools precisely define part dimensions, surface finish, tolerances, shape, and overall appearance.

At Ahmedabad Textiles Industry’s Research Association (ATIRA), we are proud to offer specialized tool and part design services tailored to meet the needs of industries working with composite materials.

Our tool design process meticulously considers molding strategy, release strategy, and manufacturing process compatibility. This comprehensive approach ensures optimal performance and seamless integration with your production processes.

Our expertise spans across various composite manufacturing processes, including Vacuum Bagging, Hand Layup, Infusion, and Pultrusion. Additionally, we excel in thermal analysis to ensure optimal tool performance in varying temperature environments.

Our Services:

Composite Design

At ATIRA, we possess extensive experience in various composite component manufacturing techniques. Our expertise enables us to evaluate the pros and cons of each method and recommend the most suitable manufacturing solution for each specific project. Below are some of the common options we offer:

- Hand Lay-Up

- Resin Transfer Molding (RTM)

- Autoclave Molding

- Compression Molding

- Pultrusion

Our tailored approach ensures that we deliver optimal solutions tailored to your unique requirements.

Customized Tool Design: We excel in providing specialized mold design services tailored to the needs of composite part manufacturing. Our expertise ensures that your production processes are efficient, precise, and of the highest quality.

Composite Tooling: The manufacture of composite product and assemblies requires that some kind of accurate repeatable tool surface and be capable of withstanding repeated exposures to the cure cycle environment of high temperature and pressure. One of the most critical parameters in the design of tooling for composites is the difference between the coefficient of thermal expansion (CTE) of the tool being designed and of the composite product being fabricated.

Testing

Our expertise encompasses comprehensive composite testing, ranging from specimen manufacture to Mechanical, thermal, fire retardant, electrical and environmental testing. We ensure that every aspect of the composite material is rigorously evaluated to meet the highest standards of performance and durability.

By collaborating closely with our customers, we gain a comprehensive understanding of their needs, allowing us to assist with component design, material selection, and process definition to achieve optimal results. We provide valuable support in optimizing the design of both prototype and production tooling, ensuring superior quality and efficiency in manufacturing.

Contact : composites-research@atira.in