Composite Materials Testing and Analysis

What is a composite material?

A composite material can be defined as an artificially prepared or natural multiphase that exhibits significant properties of constituent material resulting in a superior and stronger product.

Being formed by the combination of two or more materials that have different characteristics, Composite materials open a wide window for application in various engineering sectors like Aerospace, defense, Automobile, etc.

Applications of composites

➢ Automobiles industries: Automobile parts like components of an engine, spray nozzle, tires, etc.

➢ Aeronautical applications: structural components like wings, body & stabilizer of aircraft, etc.

➢ Marine applications: shaft, hulls, spars, and other parts of ships.

➢ Safety equipment like helmets.

➢ Sports equipment like tennis rackets, golf sticks, other safety equipment.

➢ Communication Industry like preparation of antennae and electronic circuit boards.

Constituents of composites

Two essential constituents of composites are:

- Matrix phase: It is the continuous body constituent (Dispersion phase) which encloses the composite and gives its bulk form. It may be polymer, metal or ceramic material.

- Dispersed phase: It is the Structural constituent (Dispersed phase) which determines internal structure of the composite and gives its bulk form. It may be Fiber, Particulate, Flakes or Whisker.

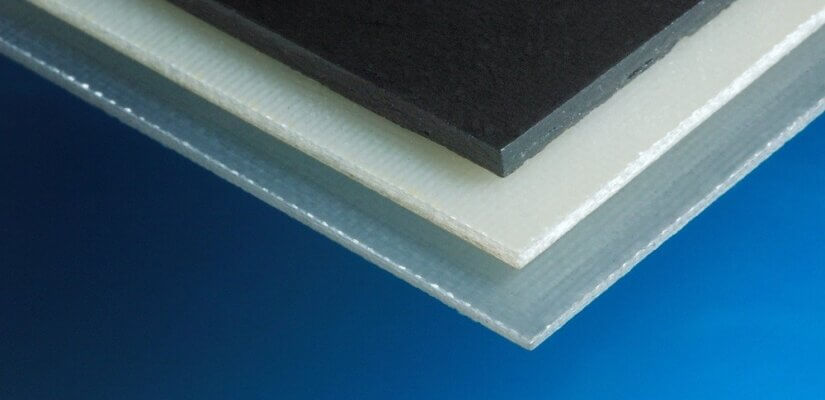

Types of composites

Depending upon the type of Matrix and Reinforcement, Composite materials are categorized into,

Need of testing and analysis of composite materials

As per Theories, Composite materials are being used from ancient times in direct or indirect ways, either in conventional or non-conventional forms.

Research made worldwide has proved that composite materials exhibit extraordinary properties. Hence most of the world is adopting modern composite materials over conventional engineering materials.

Now the question arises,

“How come it has been proved that Composites are better than Conventional materials”

Answer: “Testing and analysis of composite materials”.

Thorough Testing practices and Standards have helped to evaluate the performance of composite materials. The data derived from composite materials testing and analysis can be used to compare the composite materials against conventional materials.

Composite materials testing plays a vital role across the composite’s supply chain and product life cycle. A range of challenges in regards to safety, quality, process control, regulatory compliance, and performance is encountered. Whether you are a base chemical provider, additive supplier, fibre manufacturer, or end-user, overcoming these challenges can give your business a significant commercial advantage.

Some of the important advantages of composite materials are,

- Corrosion resistance

- Life and durability

- Good mechanical and electrical properties.

- Ease of manufacturing

Types of composite materials testing and analysis

A. Mechanical testing

The characterization of composites for mechanical properties is very important from a design and analysis as well as a life prediction point of view.

The mechanical and physical testing of polymers and their composites is vital to determine the material properties for use in the design and analysis of the product, quality control, application performance requirements, and production process.

The mechanical and physical testing ensure the material complies with performance requirements.

Mechanical testing of composites includes tensile (tension), flexural, impact, shear, and compression, and physical testing includes water absorption, density, void content, hardness, and scratch resistance.

Besides these, many other standardized bearing strength tests as per ASTM D 5961 and interlaminar fracture toughness tests to ASTM D 5538 are reported as mechanical tests on composites.

Tensile test:

Tensile testing is a destructive test process that provides information about the tensile strength, yield strength, and ductility of the metallic material. It measures the force required to break a composite or plastic specimen and the extent to which the specimen stretches or elongates to that breaking point.

Tensile testing of composites is generally in the form of basic tension or flat-sandwich tension testing in accordance with standards such as ISO 527-4, ISO 527-5, ASTM D 638, ASTM D 3039, and ASTM C 297.

The test specimen is prepared in accordance with standards applicable for the testing (Specimen shown below in images A and B) and subjected to tensile load with the help of a Universal testing machine. Such tests produce stress-strain diagrams used to determine tensile modulus.

Tensile testing also provides tensile strength (at yield and at break), tensile modulus, tensile strain, elongation, and percent elongation at yield, elongation, and elongation at break in percentage.

Flexural test:

The flexural test measures the force required to bend a beam under three-point loading conditions, and it is generally applicable to both rigid and semi-rigid materials, resins. The data is often used to select materials for parts that will support loads without flexing.

The most common flexural testing of plastics, polymer composites, and large fiber-reinforced plates involves three-point and four-point bend testing as per ISO 178, ASTM D 790, and ASTM D 6272 to ensure suitability under various conditions for better insight into their properties and to ensure that they are suitable for the intended application.

A variety of specimen shapes can be used for this test, but the most commonly used specimen size for ASTM is 3.2 mm 12.7 mm 125 mm Most commonly in the flexural test, the specimen lies on a support span, and the load is applied to the center by the loading nose producing three points bending at a specified rate.

The parameters for this test are the support span, the speed of the loading, and the maximum deflection for the test.

These parameters are based on the test specimen thickness and are defined differently by ASTM and ISO. Flexural testing also gives a semiqualitative idea of the fiber/matrix interfacial strength of a composite.

Flexural properties testing provides editable and raw data on flexural stress at yield, flexural strain at yield, flexural stress at break, flexural strain at break, flexural stress at 3.5% (ISO) or 5.0% (ASTM) deflection, flexural modulus, and stress/strain curves.

Impact test:

The impact test is designed to determine how a specimen of a known material such as polymers, ceramics, and composites will respond to a suddenly applied stress.

The impact test is explicitly used for evaluating the toughness, brittleness, notch sensitivity, and impact strength of engineering materials to resist high-rate loading [8,9].

The ability to quantify the impact property is a great advantage in product liability and safety. Impact test specimen types include notch configurations such as V-notch and U-notch. Impact testing most commonly consists of Charpy and Izod specimen configurations.

The Izod impact test differs from the Charpy impact test in the way that the notch is positioned facing the striker. ASTM D256, ISO 180, and ASTM D are some of the standards for pendulum impact testing.

In this test, a specimen is machined to a square or round section, with either one, two, or three notches. The Izod impact test consists of a pendulum with a determined weight at the end of its arm swinging down and striking the specimen while it is held securely in a vertical position (Shown in fig C & D).

The impact strength is determined by the loss of energy of the pendulum as determined by precisely measuring the loss of height in the pendulum’s swing. Also, the impact strength is defined as the tendency of polymer composites to endure high-energy impact without breaking or fracturing.

It is being reported that in fiber-reinforced polymer composites and hybrid composites the impact properties are governed by the properties of the individual fibers used for hybridization, interlaminar, and interfacial adhesion between the fiber and the matrix.

Besides the Pendulum Impact test, one more method is used to evaluate the resistance of the material to sudden impacts i.e. Drop Weight Impact test.

In this test, Specimen is hit by an indenter caring a weight or mass from a certain specified height. The energy induced by falling mass on the specimen is recorded and is used to evaluate the impact strength of the material. These tests are carried out as per ASTM D 7136M-05, ASTM D 3763, and ISO 6603.

Compression test:

Composite compression testing methods provide a means of introducing a compressive load into the material while preventing it from buckling.

Compression testing determines the behavior of materials under a crushing load, and the compression and deformation at various loads are recorded to calculate compressive stress and strain. The most common testing standards include ASTM D 695, ASTM D 3410, and ISO 14126.

Interlaminar shear strength test:

The interlaminar shear strength (ILSS) is another important mechanical test that provides information about the quality of the resin-fiber bond.

The ILSS of unidirectional laminates and carbon fiber reinforced plastics are usually determined through a three-point bending test, where the resistance to interlaminar shear stress is kept parallel to the layers of the laminate and is measured.

Shear test:

Shear tests are used to determine the attributes such as shear strain, shear stress, shear modulus, and failure mode since the awareness of the “deformable” mechanical properties of plastics and polymer composites is essential to extend their applications.

Shear testing can be used for quality control, comparative testing, and finite element (FE) analysis of new materials.

Shear strength results are important to design a wide variety of materials like adhesives, plastics, films, and sheet products that tend to be subjected to various “shear loads,” or in applications where factors such as crushing.

loads are a risk. Standards for the shear tests include ASTM D3518 and ISO 14129. The ASTM C 273, and ASTM D 2344.

Hardness:

A hardness test is Performed on materials to check resistance to indentation.

Different Hardness testing practices are used on composite materials like:

- Rockwell hardness

- Shore hardness

- Barcol hardness

Apart from the above described mechanical properties, some physical properties are also evaluated to understand the behavior of composite material.

- Water/moisture absorption test: To evaluate the percentage of moisture or water absorbed by the material. ASTM D 570 is the standard practice for this test.

- Resin content or fiber content: To evaluate the Percentage of Fiber/Reinforcement or Percentage of Matrix in composite product.

- Density Measurement: Density and specific gravity of material is evaluated as per ASTM D 792.

B. Electrical testing

The electrical properties of composites are very important to a wide range of industries such as automotive, aerospace, building products, marine, etc.

Electrical tests, in general, are measurements of the resistance, conductivity, or charge storage either on the surface or through the material.

Various factors such as dielectric strength, volume, and surface resistivity are crucial to gauge the nature of the material.

- Dielectric strength:

Dielectric strength, also known as dielectric breakdown strength (DBS), is the maximum electrical potential that a material can resist before the electrical current breaks through the material and the material is no longer an insulator. DBS is tested per ASTM D149 and measured in kV/mm or V/mil.

- Insulation Resistance:

An insulation resistance (IR) test measures the total resistance between any two points separated by electrical insulation. The test, therefore, determines how effective the dielectric (insulation) is in resisting the flow of electrical current. Such tests are useful for checking the quality of insulation, not only when a product is first manufactured but also over time as the product is used.

- Volume resistivity and Surface resistivity:

Surface resistivity is the resistance to leakage current along the surface of insulating material. Volume resistivity is the resistance to leakage current through the body of insulating material. The higher the surface/volume resistivity, the lower the leakage current and the less conductive the material is.

- Dry Arc Resistance

When electric current travels across an insulator’s surface, it can become conductive due to damage, erosion, or other factors. Arc resistance is a measure of the time required to make an insulating surface conductive under a high voltage/ low current arc in carefully controlled laboratory conditions.

In other terms, arc resistance is the ability of the plastic material to resist the action of a high voltage electrical arc and resist the formation of a conducting path along its surface under a given time.

The most generally used standard test to calculate arc resistance is ASTM D495.

C. Thermal properties testing

Some raw materials used in the manufacture of composite materials can be negatively impacted by the effects of temperature and humidity. It is therefore essential to ensure they are stored within highly controlled environmental conditions prior to use.

Differential scanning calorimetry (DSC) is one of the common tests used to check the cure and confirm the material’s thermal properties. DSC is one of the most important test types when discussing quality control. DSC can provide information on the physical structure of the material via important thermal transitions such as glass transition temperature (Tg) [link], melting temperature (Tm), crystallization temperatures, percent crystallinity, enthalpy of melting and crystallization, specific heat capacity (Cp) and oxidation induction time (OIT).

Dynamic mechanical analysis (DMA) is a technique that can be used to provide information on the material’s physical structure via its viscoelastic mechanical properties. The test allows the material’s response to a sinusoidal force during a temperature or frequency sweep to be obtained. DMA can be used to determine the mechanical properties (mechanical modulus or stiffness and damping) of the composite and important thermal transitions of the adhesive, such as the glass transition temperature and the degree of cure of polymer and composite materials.

Thermogravimetric analysis (TGA) can be used to provide information on the material’s chemical and physical structure via thermal decompositions. TGA provides information on the temperature and rate of decomposition of materials and the number of volatiles and fillers they contain. With advanced analysis software, characteristic temperatures such as melting points and decomposition temperatures can also be evaluated.

Thermal conductivity refers to the intrinsic ability of a material to transfer or conduct heat. It is also defined as the amount of heat per unit time per unit area that can be conducted through a plate of unit thickness of a given material, the faces of the plate differing by one unit of temperature.

D. Heat and flame testing

Flammability Testing:

Flammability test methods measure how easily materials ignite, how quickly they burn, and how they react when burned.

There are several methods for fire resistance or flammability. Depending on the materials and applications of the materials there are different methods or practices for flammability testing like,

– UL 94, UL 94HB, 94V, 94VTM, 94-5V, 94HBF, 94HF or UL 94 V-0, V-1 and V-2

– Limiting oxygen index (LOI)

– Vertical burning test (VC)

– Flammability ASTM D635, ISO 3795

Flammability testing is a critical part of ensuring safe and trustworthy products. Industry applications for flammability test methods include textiles and consumer goods, aerospace and transportation, bedding, and furniture materials.

Vertical and horizontal flammability testing

The materials are placed over a Bunsen burner either vertically or horizontally, depending on the specification. During a vertical flammability test, a material is observed for the duration of time it burns after the igniting flame is removed, how much of the specimen burns, and whether it drips flaming particles.

In contrast, horizontal flammability tests observe if the material continues to burn after the test flame is removed, and then calculate the rate at which the specimen burns.

Limiting oxygen index (LOI)

The limiting oxygen index (LOI) is the minimum concentration of oxygen, expressed as a percentage, that will support the combustion of a material. It is measured by passing a mixture of oxygen and nitrogen over a burning specimen, and reducing the oxygen level until a critical level is reached. The standard test method for evaluating the LOI of composite material is ASTM D 2863.

Toxicity:

Toxicity of products of combustion in terms of small molecular species is evaluated to ensure the safe behavior of materials in case of fire hazard or combustion. Also, combustion characteristics of natural & synthetic materials can be compared using this testing.

NES 713 and NCD 1409 are the common practices for this testing. Around 14 types of effluent gasses can be measured in PPM using these practices.

This testing finds application in products used in mass transport, defense, aerospace, etc.

Smoke density test:

This test is for the Determination of smoke generated by solid materials & assemblies mounted in a vertical orientation within the chamber. This test measures the amount of smoke given off by a material that is burning or smoldering.

Standard Test Methods for this testing include ASTM E 662, ISO 5659, and NFPA 258.

These tests are carried out to ensure the safe behavior of the material. Also, as per ISO 5659 and EN45545, this parameter is evaluated to determine the hazard level of the material.

Cone calorimeter test:

To evaluate the amount of heat released or evolved from the substance this test is carried out. Cone calorimeter Measures Rate of heat release, smoke release rates, time to ignition, Mass loss rates, effective heat of combustion.

The Cone Calorimeter is a fire testing tool based on the principle that the amount of heat released from a burning sample is directly related to the amount of oxygen consumed during the combustion. The amount of heat a material generates is directly aligned with the severity of a fire, such as fire growth rate. To assess a material’s flammability, it is exposed to an external radiant heat source.

A sample is placed below a cone-shaped radiant heater and typically exposed to an external flux from the heater. Once enough pyrolysis products are generated, ignition occurs. The combustion products travel through the Cone heater and through an instrumented exhaust pipe. The values measured/calculated are, the time to ignition, the mass-loss rate during combustion, time to and the value of the maximum amount of heat released during combustion, and the total amount of heat released during the test. The standard Test method for this test is ISO 5660-1:2002.

Smoke opacity:

To Determine the Deterioration of visibility due to smoke produced because of combustion of the material.

In this test, the material is burnt in a closed chamber, and visibility through the smoke generated is evaluated using a Lux meter.

This test is commonly done to evaluate components used in mass transport as per the UIC-564-2 standard.

Spread of flame:

Flame spread tests aim at measuring the tendency of a flame to propagate over a substrate and directly correlate to surface flame propagation in a real fire scenario.

As per the UIC-564-2 standard, it is very important to evaluate the spread of Flame.

In this test, the Critical area of spread of flame and afterglow time is calculated to evaluate the burning behavior and resistance of the material to the spread of flame.

Lift spread of flame:

The Spread of Flame Apparatus is an important test for comparing the performance of essentially flat materials, composites or assemblies, which are used primarily as the exposed surfaces of walls. ISO 56582 and ASTM E1321 allow wider use of the test beyond marine applications. The major differences between ISO 56582 and the IMO test are that ISO 56582 is limited in scope to testing the spread of flame over vertical specimens and does not include the stack for estimating the heat release rate.

Sector wise requirement of testing and analysis of composite materials

As discussed, Composite materials find applications in various engineering sectors and most of the world is adopting modern composite materials replacing conventional materials. Hence a wider scope for testing and analysis of composite materials has been generated.

Depending upon the sectors and application, different properties and characteristics of composite materials are evaluated.

1. Composite materials testing for Structural members.

Composite materials especially Pultruded profiles, find their application as support structures, structural members in industrial or civil applications.

Testing’s carried out:

Mechanical properties like Tensile properties, compressive properties, flexural properties, bearing strength, shear strength, Physical properties as per ASTM, ISO, BS, and IS standards.

Full section bending test, Static loading Test, Full section shear modulus test etc

Flammability test:

UL-94, Spread of flame as per ASTM D 635 and Limiting oxygen index as per ASTM D 2863.

Electrical test:

Dielectric strength, Break down the voltage as per ASTM D 149, Critical trackability index, and Dry Arc Resistance Test.

2. Automobile components:

Testing carried out:

Mechanical properties like Tensile properties, compressive properties, flexural properties, bearing strength, shear strength, Physical properties as per ASTM, ISO, BS, and IS standards.

Flammability test:

UL-94, Spread of flame as per ASTM D 635 and Limiting oxygen index as per ASTM D 2863.

Electrical test:

Dielectric strength, Break down the voltage as per ASTM D 149, Critical trackability index, and Dry Arc Resistance Test.

Heat and flame testing:

Cone calorimeter test as per ISO 5660, EN45545-2.

Fire resistance characteristics as per UIC-564-2.

Smoke density testing as per EN45545-2, ISO 5659.

Toxicity Index testing as per NCD 1409, NES 713.

3. Composite materials for Mass transports, and Aerospace

Testing carried out:

Mechanical properties like Tensile properties, compressive properties, flexural properties, bearing strength, shear strength, Physical properties as per ASTM, ISO, BS, and IS standards.

Flatwise mechanical strength as per ASTM C 297

Flammability test:

UL-94, Spread of flame as per ASTM D 635 and Limiting oxygen index as per ASTM D 2863.

Electrical test:

Dielectric strength, Break down the voltage as per ASTM D 149, Critical trackability index, and Dry Arc Resistance Test.

Heat and flame testing:

Cone calorimeter test as per ISO 5660, EN45545-2.

Fire resistance characteristics as per UIC-564-2.

Smoke density testing as per EN45545-2, ISO 5659.

Toxicity Index testing as per NCD 1409, NES 713.

Toxicity of smoke as per EN 45545-2.

Flooring Radiant Panel Testing for flooring materials.

Lift spread of flame /IMO testing

4. FRP gratings ,Walkways and Cable trays(Civil constructions)

Testing carried out:

Mechanical properties like Tensile properties, compressive properties, flexural properties, bearing strength, shear strength, Physical properties as per ASTM, ISO, BS, and IS standards.

Full section bending test, Static loading Test, etc.

Flammability test:

UL-94, Spread of flame as per ASTM D 635 and Limiting oxygen index as per ASTM D 2863.

UV Resistance test As per ASTM G154

5. Composite materials for Ship Building

Testing carried out:

Mechanical properties like Tensile properties, compressive properties, flexural properties, bearing strength, shear strength, Physical properties as per ASTM, ISO, BS, and IS standards.

Flammability test:

UL-94, Spread of flame as per ASTM D 635 and Limiting oxygen index as per ASTM D 2863.

UV Resistance test As per ASTM G154

6. FRP storage Tanks testing

Testing carried out:

Mechanical properties like Tensile properties, compressive properties, flexural properties, bearing strength, shear strength, Physical properties as per ASTM, ISO, BS, and IS standards.

Flammability test:

UL-94, Spread of flame as per ASTM D 635 and Limiting oxygen index as per ASTM D 2863.

UV Resistance test As per ASTM G154

Ageing test in a hot air oven,

Ageing test by immersion into solvents or desired liquids as per UL-1316.

7. Composite laminates testing

Testing carried out:

Mechanical properties like Tensile properties, compressive properties, flexural properties, bearing strength, shear strength, Physical properties as per ASTM, ISO, BS, and IS standards.

Flammability test:

UL-94, Spread of flame as per ASTM D 635 and Limiting oxygen index as per ASTM D 2863.

UV Resistance test As per ASTM G154

Electrical test:

Dielectric strength, Break down the voltage as per ASTM D 149, Critical trackability index, and Dry Arc Resistance Test.

Insulation Resistance Test.

Heat shock and Heat distortion.

Volume resistivity and surface resistivity.

8. Composite materials for defense applications

Composite materials testing carried out:

Mechanical properties like Tensile properties, compressive properties, flexural properties, bearing strength, shear strength, Physical properties as per ASTM, ISO, BS, and IS standards.

Flatwise mechanical strength as per ASTM C 297

Drop weight Impact testing as per ASTM D 3763.

Flammability test:

UL-94, Spread of flame as per ASTM D 635 and Limiting oxygen index as per ASTM D 2863.

Electrical test:

Dielectric strength, Break down the voltage as per ASTM D 149, Critical trackability index, and Dry Arc Resistance Test.

Heat and flame testing:

Cone calorimeter test as per ISO 5660, EN45545-2.

Fire resistance characteristics as per UIC-564-2.

Smoke density testing as per EN45545-2, ISO 5659.

Toxicity Index testing as per NCD 1409, NES 713.

Toxicity of smoke as per EN 45545-2.

Flooring Radiant Panel Testing for flooring materials.

Lift spread of flame /IMO testing

ATIRA facilities

At ATIRA we have a facility for testing composite materials used in various engineering sectors.

We have a Facility for

- Mechanical testing

- Tensile properties (ASTM D 638, ASTM D 3039, ISO 527, ASTM C 297, BS 4994 & Equivalent Standards)

- Compressive properties (ASTM D 695, ASTM D 3410 & Equivalent Standards)

- Shear properties (ASTM D 2344, BS 4994, ASTM F 711, EN 2563, ISO 14130 & Equivalent Standards)

- Flexural properties (ASTM D 790, EN 2562, ISO 14125 & Equivalent Standards)

- Bearing strength (ASTM D 5961 & Equivalent Standards)

- Lap shear strength (BS 4994, ASTM D 3163, ASTM D 5868 & Equivalent standards)

- Peel strength (BS 4994 & Equivalent Standards)

- Impact strength (ASTM D 256, ASTM D 4812, ISO 180 & Equivalent Standards)

- Drop weight impact (ASTM D 3763, ISO 6603, ASTM D 7136 & Equivalent Standards)

- Full section bending test

- Full section shear modulus test

- Static loading test

- Bending test on FRP full sections like rods and pipes. (ASTM F 711)

- Stiffness test

- Heat deflection Temperature and VICAT softening temperature. (ISO 75-1)

- Physical testing

- Hardness (Barcol, Rockwell. Shore) (ASTM E 18, ASTM B 254, ASTM D 2583 & Equivalent standards)

- Glass content/resin content (ASTM D 3171, ISO 14127 & Equivalent Standards)

- Water absorption (ASTM D 570 & Equivalent Standards)

- Void content

- Specific gravity and Density (AST D 792, ISO 1183 & Equivalent Standards)

- Resistance to chemicals

- Wicking resistance.

- Electrical testing

- Breakdown voltage testing (ASTM D 149 & Equivalent standards)

- Dielectric Strength (ASTM D 149 & Equivalent standards)

- Dry arc resistance (ASTM D 495)

- Glow wire test

- Comparative tracking Index

- Flammability testing

- UL-94

- Horizontal flammability as per ASTM D 635

- Limiting oxygen Index (ASTM D 2863, ISO 4589, & Equivalent Standards)

- Toxicity Testing As per NCD 1409 and NES 713

- Thermal properties testing

- DSC (Differential scanning calorimetry) (ASTM D 3418 & equivalent standards)

- DMA (ASTM D 7028)

- Heat and flame testing

- Deterioration of Visibility due to smoke generated (UIC 564-2)

- Lateral spread of flame (UIC 564-2)

- Lift spread of flame/ IMO

- Cone calorimeter test (ISO 5660, EN 45545-2)

- Smoke density (ISO 5659, EN 45545-2)

- Flooring radiant panel

- Single flame source test.

- Non-destructive testing

- Ultrasonic scanner

- X-rays

- Dynamic mechanical analysis of materials and fatigue testing.

- Immersion ageing of FRP Tanks as per UL-1316.

- Ageing test of composite materials.

Composite sectors we serve:

We conduct composite materials testing for,

- Mass Transport (Railways, Metro-Rails, Bullet trains, Public transport buses etc)

- Structural applications

- Aerospace and aviation sectors

- Ship building

- Storage tanks for industrial applications (Chemical, Fuels etc)

- Sewerage plants

- Cable trays for Electrical installations.

- Automobile components

- Wind energy applications

- Effluent gas treatment plants

- Solar power plants

- Defense sector

- Composite Laminates

Also, We serve,

- Adhesives manufacturing,

- Resin or Matrix manufacturing sectors

For composite materials testing, related queries please contact:

Composite Materials Testing Laboratory

Ahmedabad Textile Industry’s Research Association (ATIRA)

P.O. Ambawadi Vistar, Ahmedabad- 380 015

Phone : +091-79-26307921-22-23 (Ext : 382)

Fax : +91-79-26304677,Mobile:9096014577

Email: composites_testing@atira.in