Geotechnical textiles are technical textile products manufactured from natural and man-made fibers using woven, knitting and non-woven methods, and are used in geological applications involving rock, soil, or other natural elements in civil engineering projects. Geotechnical textiles are gaining increasing acceptability both in the domestic and in international markets in view of their special technical attributes such as drapability, inertial strength, ecological efficiency, low maintenance, customizable fabric, fineness, low extensibility, and commercial advantages, like easy availability of customized fabric and comparative economy. Geotechnical textiles are being increasingly used globally to address dangers to infrastructure caused by degradation and natural disasters. The transportation sector will be a key beneficiary of geosynthetic products and their abilities in enhancing the durability of roads, improving drainage facilities, and facilitating construction of erosion-preventing structures.

Geosynthetic is manufactured from a polymeric material that is used with soil, rock, or other geotechnical-related material. Most geosynthetics are made from synthetic polymers of polypropylene, polyester, or polyethylene. Geosynthetic products available today include, but are not limited to, Geowebs, Geogrids, Geonets, Geomeshes, Geocomposites, and Geotextiles. Geotextile is a permeable Geosynthetic made of textile materials.

Primary advantages of Geosynthetics

- Relatively low cost for many applications

- Ease and convenience for many applications

- Quick and effective protection against erosion problems

- Design methodologies are available for many uses

- Many varieties of geosynthetic products are available to meet specific needs

- May be removed and reused if economically feasible

The North Eastern Region (NER) of the country comprises of eight states, Arunachal Pradesh, Assam, Manipur, Meghalaya, Mizoram, Nagaland, Sikkim, and Tripura. The region occupies about 5.6% of the total geographical area of the country. In spite of rich biodiversity and ethnocultural richness, the region has its share of problems in terms of infrastructural inadequacies and connectivity, etc. Varied climatic and geophysical conditions of this region make the general infrastructure of the region, such as roads, fragile and susceptible to frequent damages. Due to heavy rains and unstable geographical conditions, the slopes of the hills lead to frequent landslides thereby damaging roads and causing serious erosion problems. In spite of heavy rains, the region faces a serious water crisis as the rainwater cannot be retained and stored. Traditional civil engineering solutions for the construction of hill roads in this landslide prone and sinking terrains have not been very successful in retaining the infrastructure for a longer duration, needing frequent restoration and repair leading to heavy expenses.

Geotechnical textiles are used the world over to address some of these problems with a proven track record as a technology world over. Therefore, these materials carry a huge potential for use in these regions in projects relating to road construction, hill slope protection, and erosion control, and reservoir lining for water retention.

Geo-climatic and topographic characteristics in NER make infrastructure in this region amenable to the use of geotechnical textiles. The region is fraught with heavy rainfall, fragile terrain, landslides and sinking zones, river bank erosion, high seismic activity, weak soil conditions, young mountains, and problems in water harvesting and storage. The North Eastern Region of India is yet to adopt this innovative technology, barring a few roads in Assam, which were taken-up as pilot projects under PMGSY.

The application of geotechnical textiles components in riverbank protection has not been covered/ considered in this scheme

In order to promote and increase the usage of geotechnical textiles in civil engineering projects inter-alia road construction, slope protection and water reservoirs in the North Eastern Region, Ministry of Textiles, Government of India has formulated a Scheme for Promoting Usage of Geotechnical textiles in the North Eastern Region, for five years from 2014-15 to 2018-19 with a financial outlay of Rs. 427 Crores, the operation of the scheme is extended till March 2020.

The scheme consists of three components, Hard Intervention, Soft intervention, and Administration.

ATIRA is involved in Soft intervention of the scheme which includes the following:

- Site inspection, Geotechnical textiles Solution Design, including the hiring of experts and DPR preparation

On-site testing, creation of testing facilities and actual testing support to the projects

Workshops / Seminars / Training and Capacity Building, including Promotional efforts

Specification formulation and product customization, simulation modeling

Market studies / User Manual/ Publications material

Besides, as part of the intervention ATIRA undertook the following activities to facilitate the operation of the scheme:

- Co-ordination among the stakeholders

- On site monitoring

- State Level Co-ordination Committee (SLCC) Meetings

- Co-ordination with the suppliers for delivery, installation & Certification

- Assistance to Textile commissioner office, preparation of MIS

During the operation of the scheme from March 2015 to March 2019, ATIRA undertook 32 projects consisting of Road construction, Slope Protection and Water lining and reservoirs in North Eastern Region, of which 13 are completed and 7 are underway. These projects are undertaken mainly in Manipur, Meghalaya and Mizoram states. The concerned state governments where the projects were undertaken are satisfied with the execution and benefits of the projects and are keen to explore more projects in their regions

Geo-Textile – Testing & Evaluation Facilities

Index Testing Parameters

The broad steps of Adequacy Certification are:

1) Fabric Weight (GSM) –ISO 9863-1& 2

2) Fabric Thickness – ISO 9864

3) Grab Tensile Strength : (ASTM D 4632, IS 1969, ISO 13934-2)

4) Wide width Tensile Strength (BS EN ISO 10319, ASTM D 4595)

5) Puncture Resistance

6) Wide Width Strength

7) Tear Strength

8) Trapezoidal Tear Strength (ASTM D 4533)

9) Pyramid Puncture (ASTM D 5494)

10) Index Puncture (ASTM D 4833)

11) CBR Puncture (ASTM D 6241, ISO 12236)

12) Bursting Strength (ASTM D 3786,BS EN ISO 13938-1,ISO 13938-1)

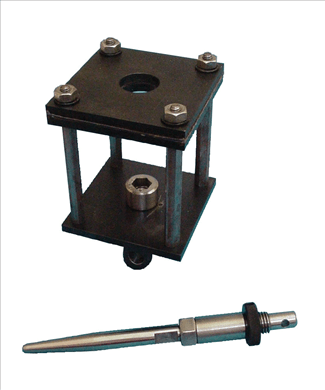

13) Dynamic Cone Drop Apparatus (ISO 13433)

14) UV Resistance (% Retained @ 500hrs) ASTM D 4355

15) System for measuring Resistance to weathering (DIN EN 12224)

16) Apparent Opening Size (AOS)- ISO 12956

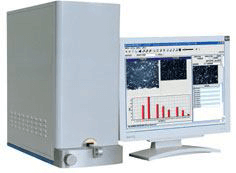

17) Porometer for Pore size analysis

18) Falling Headwater permeability (EN ISO 11058 and ASTM D4491-99a)

Water Permeability Perpendicular to the plane of the geosynthetic (without load, falling head)

Water Permeability: perpendicular to the plane of the geosynthetic (with load)

Water Permeability in the plane of the Geosynthetic (with load)

- Constant Head Water Permeability (ISO 11058)

- In-Plane Permittivity (ISO 12958)

- Carbon Black Content Analyzer

19) Carbon Black Dispersion Analyzer

20) Melt Flow Index Tester