Jute Fiber Composites: A Sustainable Socket Material for Prosthetic Legs

Prosthetic limbs play a crucial role in enhancing the mobility and quality of life for individuals with limb loss. The socket, which connects the residual limb to the prosthetic limb, is a critical component that directly influences comfort, fit, and overall functionality. Traditional socket materials often involve synthetic fibers and plastics, which may not be environmentally friendly or offer optimal comfort. However, a sustainable and innovative solution has emerged in the form of socket materials made from jute fiber composites.

Embracing Sustainability:

Jute, a natural fiber derived from the stems of the jute plant, offers several ecological benefits. It is a renewable resource with a low carbon footprint and requires minimal chemical treatment during processing. By utilizing jute fiber composites for prosthetic sockets, we can contribute to a more sustainable and eco-friendly approach to prosthetics.

Enhanced Comfort and Fit:

One of the key advantages of using jute fiber composites in prosthetic sockets is the enhanced comfort and fit they provide. Jute fibers possess excellent moisture-wicking properties, allowing for better breathability and reduced sweating. The natural flexibility and softness of jute fibers ensure a gentle and comfortable interface between the residual limb and the socket, minimizing the risk of skin irritation or pressure sores.

Customization and Adaptability:

Jute fiber composites offer remarkable adaptability, enabling customization according to individual needs. The inherent flexibility of jute fibers allows for precise shaping and contouring of the socket to match the unique anatomy of the residual limb. This personalized fit ensures optimal weight distribution and stability, resulting in improved balance and mobility for the user.

Manufacturing Considerations:

The manufacturing process for jute fiber composites involves impregnating the jute fibers with a polymer matrix followed by curing. This process can be performed using various techniques, including vacuum infusion or compression molding, depending on the desired properties and complexity of the socket design.

Strength and Durability:

Contrary to common misconceptions about natural fibers, jute fiber composites exhibit impressive strength and durability. When combined with appropriate resin systems, jute fibers provide sufficient structural integrity to withstand the stresses and strains encountered during daily activities. This ensures longevity and reliability in prosthetic sockets, reducing the need for frequent replacements.

Aesthetics and Design:

The socket material plays a crucial role in distributing the forces exerted during locomotion and absorbing impacts. Natural fiber composites, including jute fiber composites, exhibit excellent shock absorption properties, reducing the strain on the residual limb and providing a cushioning effect. This can enhance user comfort and minimize the risk of injuries or discomfort during activities.

Biocompatibility and Skin Health:

Natural fiber composites are known for their biocompatibility, which is crucial for socket materials. Jute fiber composites have a low tendency to cause skin irritation or allergies, making them suitable for individuals with sensitive skin. Additionally, the moisture-wicking properties of jute fibers help maintain a dry and breathable environment, reducing the risk of skin-related issues.

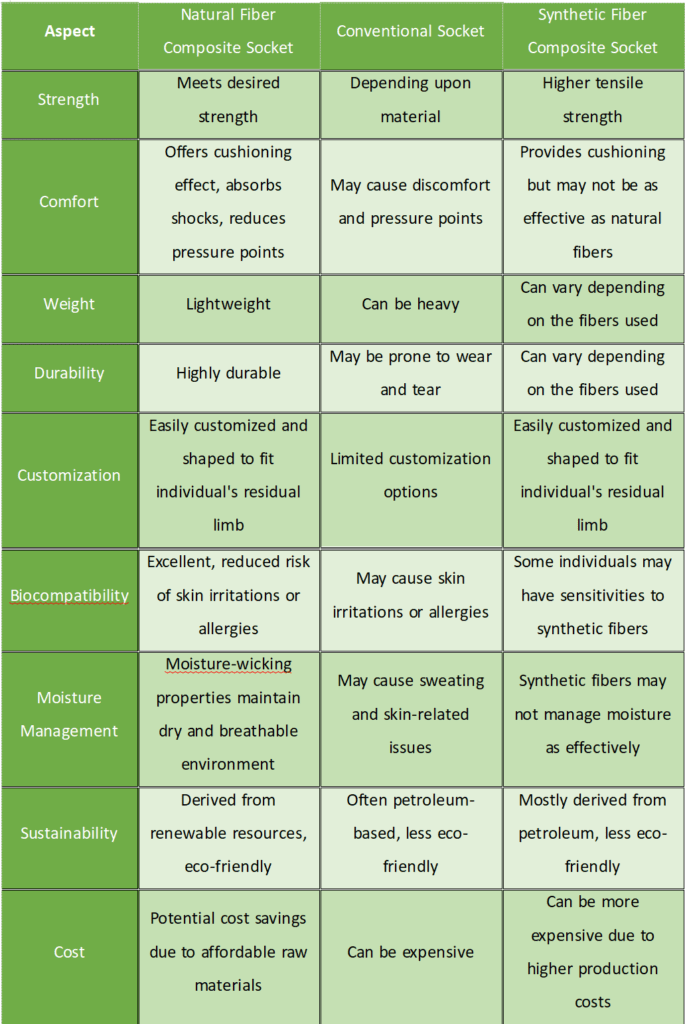

Comparison of Natural fiber composite-based socket over other synthetic and conventional socket materials

The utilization of jute fiber composites in the fabrication of prosthetic leg sockets represents a sustainable and innovative approach in the field of prosthetics. By embracing jute fibers’ inherent properties, such as comfort, customization, and durability, we can revolutionize the design and functionality of prosthetic sockets. The combination of eco-friendliness, enhanced comfort, and aesthetics makes jute fiber composites an exciting material for creating prosthetic leg sockets that cater to both the physical and emotional well-being of users. This remarkable innovation holds promise for a more sustainable and inclusive future in the field of prosthetics.

ATIRA (Ahmedabad Textile Industry’s Research Association) in collaboration with the Blind People’s Association (BPA) and supported by the National Jute Board, is at the forefront of developing natural fiber-based socket materials for prosthetic legs. This groundbreaking initiative aims to revolutionize the field of prosthetics by utilizing sustainable and biocompatible materials, specifically natural fibers like jute.

The partnership between ATIRA, BPA, and the National Jute Board signifies a collective effort towards creating innovative solutions that address the needs of individuals with limb loss. By combining their expertise in textile research, prosthetic design, and support for the physical impaired community, this collaboration holds tremendous potential for transforming the lives of amputees.

Furthermore, the partnership between ATIRA, BPA, and the National Jute Board emphasizes the importance of affordability and accessibility of prosthetics. Natural fibers, like jute, are cost-effective compared to synthetic materials, making prosthetic legs more affordable for a broader population. This inclusivity is critical in ensuring that individuals from all walks of life can benefit from advanced prosthetic technologies.