Preventing Color Stains in Dyed Cotton [Reactive Dye & Ozone Tips]

Color staining and discharge stains in stitched dyed cotton garments are a common challenge, especially when dealing with reactive dyes. A typical issue is the development of light to medium pink stains post-finishing, which occurs after garment making. The root cause often lies in the cleavage of azo groups (chromophores) and unsaturated carbon-carbon linkages. Although stains form in a seemingly random manner, research suggests that atmospheric conditions with oxidizing agents in gas form are significant contributing factors.

Understanding Reactive Dyes

Reactive dyes are widely used for dyeing cotton garments due to their strong covalent bonding with cellulose fibers. These dyes contain dichlorotriazine groups, which form a bond with the fiber through substitution or addition reactions in an aqueous solution. This strong bond (with energy ranging from 80-100 kcal/mol) ensures the dye becomes an integral part of the fiber.

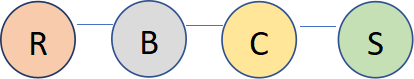

Key components of reactive dyes include:

- Reactive Group (R): Contains chlorine, fluorine, alkyl sulphones, or quaternary ammonium groups.

- Bridging Group (B): Links the reactive systems with the chromophore.

- Chromophore (C): Responsible for the dye’s color, including groups such as azo (-N=N-), anthraquinone, phthalocyanine, and triphenylmethane.

- Solubilizing Group (S): Allows the dye to dissolve in aqueous solutions for easier application.

The fixation process of reactive dyes is crucial for color durability. In this process, the reactive dye forms a covalent bond with the terminal -OH or -NH2 groups in the fiber, which is controlled by maintaining an optimal pH with alkalis like caustic soda or soda ash. The following reaction occurs during the dyeing process:

D-SO2-CH2-CH2-OSO3Na + OH-Cell → D-SO2-CH2-CH2-O-Cell + NaHSO3

Color Staining Issues in Cotton Garments

During the garment washing process, various dyeing, washing, and softening agents (like polyethylene, polyvinyl acetate, and cationic dye fixers) can contribute to the migration of dye particles, especially in the presence of oxidative conditions. Such reactions can result in unexpected stains, often involving the interaction between the garment’s metal accessories (zippers, buttons) and the chemicals used.

Factors influencing the staining of garments:

- Dyestuff and chemical concentration

- Processing temperature

- Duration of garment dyeing treatment

- Stain resistance of the garment

Accessories such as metal zippers, buttons, and badges are particularly sensitive to oxidative reactions, leading to color changes or staining. Metals like zinc and alloy components are prone to reacting with dyestuffs, causing discoloration that can worsen if garments remain wet or are exposed to humid environments for extended periods.

Ozonolysis and Its Impact on Reactive Dyes

Ozonolysis is a critical process that can lead to color staining in reactive dye-treated garments. This reaction involves the oxidative cleavage of carbon-carbon bonds by ozone, resulting in products like aldehydes, ketones, or carboxylic acids. For azo dyes, ozonolysis may yield nitrosamines, leading to further color issues.

Preventive Care for Dyed Cotton Garments

To prevent color discharge and staining in cotton garments, follow these best practices:

- Ensure thorough neutralization, rinsing, and drying after dyeing, washing, or softening processes to remove chemical residues.

- Avoid drying garments in open air, where exposure to ozone can trigger reactions.

- Handle metal accessories with care, ideally adding them during the final stages of garment treatment to prevent oxidation-related staining.

- Control moisture, pH, and processing time to reduce oxidative cleavage of dyes.

Conclusion

Understanding the chemistry behind reactive dyes and the conditions that lead to color staining can help prevent issues with cotton garments. By optimizing garment processing and handling, manufacturers can minimize the risk of stains and ensure the durability of vibrant colors.

For more tips on garment care and dyeing solutions, contact us on ctd@atira.in