Revolutionizing Sandwich Composites Panels with Carbon Triangle Cores

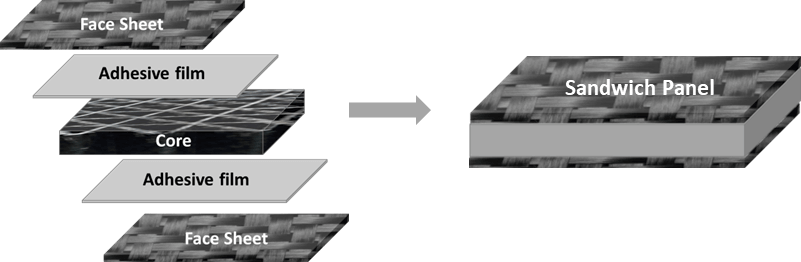

Sandwich panel design is a critical aspect of several engineering applications, from aerospace engineering to civil engineering. These panels are commonly used to make lightweight and strong structures that can withstand high loads and forces. The sandwich composite structure consists of two face sheets and a core material. The face sheets are made of high-strength materials like carbon fiber-reinforced polymer (CFRP), glass fiber-reinforced polymer (GFRP), or metal. The core material is usually made of low-density materials like foam, balsa wood, or honeycomb. The face sheets and the core material are bonded together with an adhesive. In this blog post, we will delve deeper into the world of sandwich composites panels design, exploring its history, current applications, and potential future developments.

Advantages of Sandwich Composites

The sandwich composite structure provides superior mechanical properties compared to the individual components. The face sheets provide strength and stiffness while the core material provides low density and energy absorption capability. The combination of these properties results in a lightweight yet strong structure.

Sandwich composites have several advantages over traditional materials like metals or solid composites. They have a high strength-to-weight ratio, excellent thermal and acoustic insulation properties, and resistance to impact and fatigue. They also have a high resistance to corrosion and are easily repairable.

Design Considerations for Sandwich Composites

The design of sandwich composites requires careful consideration of the core material, face sheet material, and adhesive. The core material should be lightweight, have good compressive strength, and be resistant to crushing. The face sheets should have high strength and stiffness and be resistant to buckling. The adhesive should have good bonding properties and be resistant to moisture and temperature changes.

Core structures are the backbone of various engineering applications, especially in the aerospace and civil engineering fields. Structural panels made from various materials, such as metals, papers, polymers, and ceramics, are commonly used to manufacture these core structures.

Development of Triangular Carbon Fiber-Based Core Material

In recent years, there have been several developments in the field of sandwich composites. One such development is the use of triangular carbon fiber-based core material. This type of core material has a unique triangular shape that provides superior strength and stiffness compared to traditional core materials. The triangular shape allows for better load distribution, resulting in a stronger and stiffer structure.

Triangular carbon fiber-based core materials have several advantages over traditional core materials. They have a higher strength-to-weight ratio, higher compressive strength, and better energy absorption capability. They also have better resistance to crushing and are less prone to delamination.

The use of triangular carbon fiber-based core material has revolutionized the design of sandwich composites. It has allowed for the development of lightweight yet strong structures that are suitable for various engineering applications.

Mechanical Characterization of Sandwich Composites

ATIRA has developed a new core material made from carbon fiber reinforced composite and compared it with sandwich composites made from three different core and skin materials. The aim of this study was to investigate the mechanical characterization of these sandwich composites and find the best-performing material.

After performing the mechanical characterization, it was found that the triangular carbon core with carbon face sheet had the maximum compressive and lap shear strength when compared to the other sandwich composites. This makes it an ideal choice for applications that require high compressive strength.

Table: Sandwich composite composition and designation

| Sr. no. | Sample code | Covering layer material | Core structure material |

| 1 | CCSP | Carbon | Carbon |

| 2 | CASP | Carbon | Aluminium |

| 3 | AASP | Aluminium | Aluminium |

| 4 | ACSP | Aluminium | Carbon |

In conclusion, sandwich composites are an essential class of materials that have revolutionized the design of lightweight yet strong structures. The use of triangular carbon fiber-based core material has further enhanced the properties of sandwich composites and has allowed for the development of structures that are suitable for various engineering applications. ATIRA has developed the carbon core material for structural application. The method used to manufacture the core structure was simple, cost-effective, and led to improved physical properties in the final product. The sandwich composites were made with different combinations of core and skin materials, and their lap shear strength and compression strength were evaluated. Results showed that sandwich composites with similar core and skin materials exhibited the highest lap shear and compressive strength. This study opens up exciting new possibilities for revolutionizing sandwich panel design and developing even stronger and more lightweight materials for a range of applications. As technology continues to advance, we can expect further developments in the field of sandwich composites.

The patent filed by ATIRA on this technology is a testament to its potential in the field of composite materials. The search for technology transfer partners is ongoing, and it is an exciting time for the composite material industry as a whole.

Reference:

- A. Sharma, T. Gangopdhyay, A. K. Bhuyan, A. Patel, Development of triangular carbon fiber-based core material for sandwich structural panel, In Proceeding of 60th Joint Technological Conference (JTC), held at SITRA, Coimbatore, on 11-12th Nov. 2022.

- H. Xie, H. Fang, W. Cai, L. Wan, R. Huo, D. Hui, Development of an innovative composite sandwich matting with GFRP face sheets and wood core, Rev. Adv. Mater. Sci. 60 (2021) 80–91. https://doi.org/10.1515/rams-2021-0016.

- V.S. Kathavate, K. Amudha, L. Adithya, A. Pandurangan, N.R. Ramesh, K. Gopakumar, Mechanical behavior of composite materials for marine applications-an experimental and computational approach, J. Mech. Behav. Mater. 27 (2018) 1–22. https://doi.org/10.1515/jmbm-2018-0003.

- A.C. Manalo, T. Aravinthan, W. Karunasena, M.M. Islam, Flexural behavior of structural fiber composite sandwich beams in flatwise and edgewise positions, Compos. Struct. 92 (2010) 984–995.

- A. Manalo, T. Aravinthan, A. Fam, B. Benmokrane, State-of-the-Art Review on FRP Sandwich Systems for Lightweight Civil Infrastructure, J. Compos. Constr. 21 (2017) 443–461. https://doi.org/10.1061/(ASCE)CC.1943-5614.0000729.

- D. Regaçon, A. Garay, Development of Composites Sandwich Structures Using a Core Cork, J. Mater. Sci. Eng. A. 8 (2018) 100–107. https://doi.org/10.17265/2161-6213/2018.5-6.003.

- A. Redmann, V. Damodaran, F. Tischer, P. Prabhakar, T.A. Osswald, Evaluation of single-lap and block shear test methods in adhesively bonded composite joints, J. Compos. Sci. 5 (2021). https://doi.org/10.3390/jcs5010027.