Single Shot Sizing Analysis & Application Data (Case Study)

Indian Standard

IS: 1184-1977 Specification of Maize Starch (For Cotton Textile Industry)

(Second Revision)

Size Sample: E1/E2

| PHYSICAL: | ||

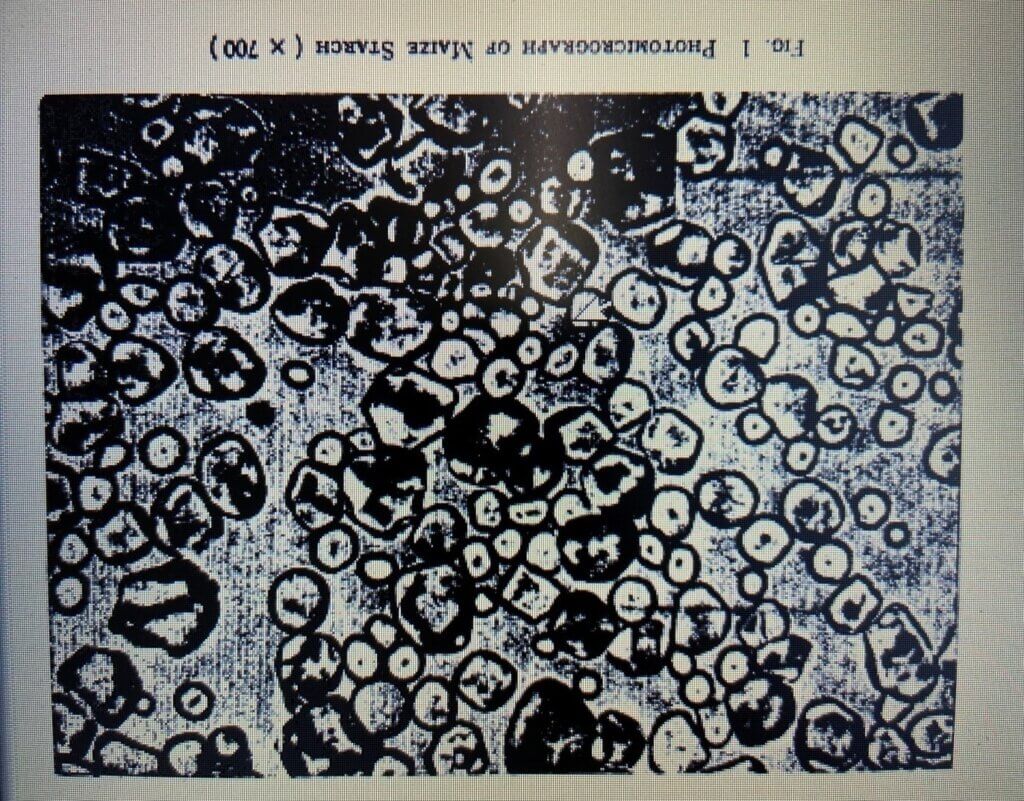

| Photomicrograph | : | Compared Favourably as Shows Uniform Particles. |

| Particle Size | : | Fine, Passes Through 180 Micron is Seaves. Free Flowing Powder, Free from Black Specks, dirt & Other adventitious Impurities. |

| Colour | : | White |

| Sr.no | Test description | Std. Min. | Actual | Remarks |

| 1 | Ash content | 0.25% | 0.319% | O.K. |

| 2 | Moisture content | 13.50% | 13.43% | O.K. |

| 3 | Cold water solubility On a dry weight basis | 0.40% | 0.29% | O.K. |

| 4 | Free acidity Ml of 0.1(n) NaOH per 100 gms dry sample | 40 ML | 08 ML | O.K. |

| 5 | The ph of 2% solution at 750 c/R.T. | 4-5 | AT 750 C-5.25 AT R.T.0 C-5.0 | O.K. |

| 6 | Petroleum hydrocarbon extractable matter | 0.25% | 0.24% | O.K. |

| 7 | Viscosity (ATIRA cup viscosity) | 7-10 Seconds | 6.5 Seconds | O.K. |

| 8 | Alkaline fluidity | 3-3..5 | 2.5 | O.K. |

Indian Standard

IS: 1184-1977 Specification of Maize Starch (For Cotton Textile Industry)

(Second Revision)

Size Sample: U1/U2

| PHYSICAL: | ||

| Photomicrograph Particles. | : | Compared favorably As Shows Uniform |

| Particle Size | : | Fine, Passes through 180 Micron Seaves. Free Flowing Fine Powder, Free From Black Specks, Dirts & other adventitious Impurities |

| Colour | : | White |

| Sr.no | Test description | Std. Min. | Actual | Remarks |

| 1 | Ash content | 0.25% | 0.28% | O.K. |

| 2 | Moisture content | 13.50% | 12.72% | O.K |

| 3 | Cold water solubility On a dry weight basis | 0.40% | 0.35% | O.K. |

| 4 | Free acidity Ml of 0.1(n) NaOH per 100 gms dry sample | 40 ML | 08 ML | O.K. |

| 5 | The ph of 2% solution at 750 c/R.T. | 4-5 | AT 750 C-4.35 AT R.T.0 C-4.80 | O.K. |

| 6 | Petroleum hydrocarbon extractable matter | 0.25% | 0.19% | O.K. |

| 7 | Viscosity (ATIRA cup viscosity) | 7-10 Seconds | 8.0 Seconds | O.K. |

| 8 | Alkaline fluidity | 3.0-3.5 | 3.0 | O.K. |

Yarn parameters

| TPI DATA | ||||

| 40s CCW | 20s O.E. | 20 KW | 30 CCW | 2/40 ELLI |

| 25.00 | 22.00 | 17.00 | 21.00 | 19.00 |

One Shot Sizing

Modified starch-based Resinous compound – One Shot Size replacement of PVA, suitable for all kinds of medium to coarse spun yarn especially for high-speed looms (40/1s to 20/1s count (Ne)).

Product Features:

- Excellent adhesion property.

- Gives a strong, flexible, and high abrasion-resistant film coating.

- Minimize warp breaks in weaving and improve weaving efficiency.

- Reduce fluff and droppings in Sizing and in Weaving, this gives a clean environment.

- Very easy to remove size prior to processing.

- Excellent result with lower pick-up resulting in a reduction of COD/BOD load of ETP.

- Improves the yarn strength due to excellent penetration, and strong binding between fibers.

- Very cost-effective with the improvement of looms performance.

- Required less cooking time as it works with low size pick-up, saving time and energy for cooking the size.

Product Profile:

- Nature Free Flowing Powder Constitution Modified corn starch

- Colour: Normal White

- Viscosity: 10 to 15 Sec. P H 5 – 8 (ATIRA CUP VISCOSITY)

- Moisture: 10% ± 2%

- Fluidity: 100 – 600 cps (B. V RVT, DVT + Model, Spindle no 3 @ 100 RPM with 10% paste at

Application Guideline:

- Recommended Where PVA free recipe is required.

- Recommended for finer to coarser counts with heavy warp density for high-speed looms. Recommended where easy desire and low pick up are required.

Application Method & Dosage: The dosage of the product depends upon the type and count of yarn, Warp density, and Machine type. Packing: 25 kg HDPE Bag packing. (25Kg full qty to be used at a time)

The above information is based on our best knowledge and experience. Details mentioned above are for a general explanation of our product and dosage may vary depending on machine type, method, and material.

Sizing With E1/E2

Process Parameters:

Size Preparation Data: –

Size Content: – 7.5%

Size Temperature: – 750 C

Immersion Time: – 3 Seconds

Spedd Of Sizing: – 5 Mts/min

Viscosity: – 8.5 Seconds (Atira Cup)

pH:- 6.5

Performance Data:-

Statimat –M/Instron ASTM D2256/D2256M-IS 1670-1991

| Sr.no | Count group (Ne) | % Elongation Value (Without sizing) | % elongation loss | Original strength (single yarn) | Post sizing strength (single yarn) | % increase |

| 1 | 40s CCW | 3.52(1.96) | 44.31 | 261.57 | 348.63 87.06 | 33.28 |

| 2 | 20s O.E. | 4.24(3.48) | 17.92 | 268.17 | 395.69 127.52 | 47.55 |

| 3 | 20 KW | 3.60(3.18) | 11.66 | 476.87 | 595.43(118.56) | 24.86 |

| 4 | 30 CCW | 3.19(1.88) | 41.06 | 310.28 | 505.92(195.64) | 62.99 |

| 5 | 2/40 ELLI | 4.41(3.37) | 23.58 | 577.55 | 636.24(058.69) | 10.16 |

Sizing With U1/U2

Process Parameters:

Size Preparation Data: –

Size Content: – 7.5%

Size Temperature: – 750 C

Immersion Time: – 3 Seconds

Spedd Of Sizing: – 5 Mts/min

Viscosity: – 9.0 Seconds (Atira Cup)

pH:- 6.8

Performance Data:-

Statimat –M/Instron ASTM D2256/D2256M-IS 1670-1991

| Sr.no | Count group (Ne) | % Elongation Value (Without sizing) | % elongation loss | Original strength (single yarn) | Post sizing strength (single yarn) | % increase |

| 1 | 40s CCW | 3.52(2.18) | 38.06 | 261.57 | 383.07(121.50) | 46.45 |

| 2 | 20s O.E. | 4.24(2.23) | 47.40 | 268.17 | 467.81 (199.64) | 74.44 |

| 3 | 20 KW | 3.60(2.65) | 26.38 | 476.87 | 558.64 (081.77) | 17.14 |

| 4 | 30 CCW | 3.19(2.11) | 33.85 | 310.28 | 459.58 (149.30) | 48.11 |

| 5 | 2/40 ELLI | 4.41(3.93) | 10.88 | 577.55 | 588.13(010.58) | 01.83 |

Sizing With U1/U2 – Elongation At Break Comparison

Sizing With U1/U2 – Strength Data Comparison

Sizing With E1/E2 – Elongation At Break Comparison

Sizing With E1/E2 – Strength Data Comparison

Effective Sizing Fundamentals

Today sizing is greatly concerned with good weaving with an optimum level of loom efficiency. The sizing mix is generally considered with two main ingredients. 1. Adhesives & 2. Lubricants. The function of the sizing is to improve the weaveability of the warp, i.e. to provide the yarn with the necessary properties to enable it to withstand the various stresses to which it is subjected in the loom. Regularity of the size mix. deposits are a primary consideration through uniform application by maintaining viscosity, adhesive power & plasticity during the entire run cycle. This outcome is highly dependent on,

- The nature of the size & the concentration of the size.

- The method of preparation or cooking (stirring, temperature & duration).

- Presence of additives.

The sizes used are generally macromolecular products in an aqueous system & their behavior is pseudoplastic. With starch rheological characteristics vary greatly with the method of cooking. There is a definite influence of concentration on viscosity. There is a great deal of debate over % of size add-on with respect to the strength and efficiency of loom operation. The following table is a useful guide.

The above information is based on our best knowledge and experience. Details mentioned above are for a general explanation of our product and dosage may vary depending on machine type, method, and material.

Size Ingredients:-

Influence of size concentration on the viscosity-time (cooking curve), Adding of soap, an electrolyte, and an oxidizing agent. (Reference: J.B.SMITH- the technology of warp sizing-London)

The above information is based on our best knowledge and experience. Details mentioned above are for a general explanation of our product and dosage may vary depending on machine type, method, and material.

The above information is based on our best knowledge and experience. Details mentioned above are for a general explanation of our product and dosage may vary depending on machine type, method, and material.