Skill Development Program for Pultrusion

Operators

ATIRA’s Center of Excellence (CoE) Composites announces Skill Development Program for Pultrusion Operators

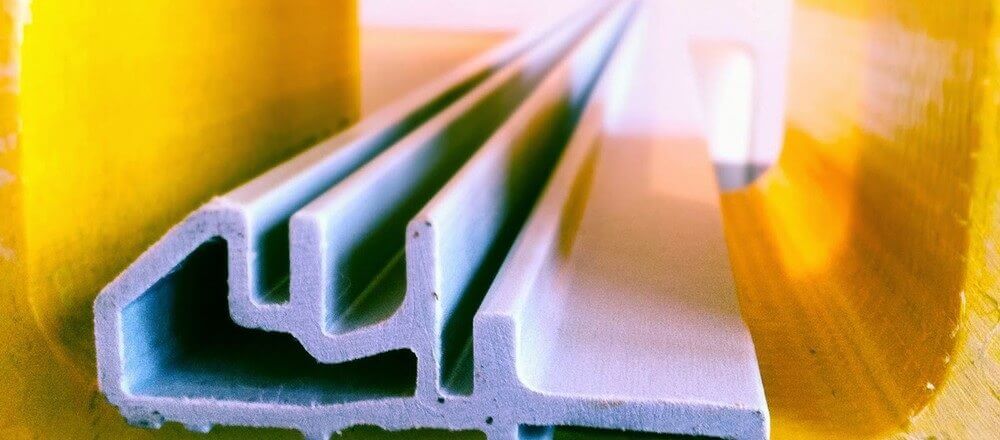

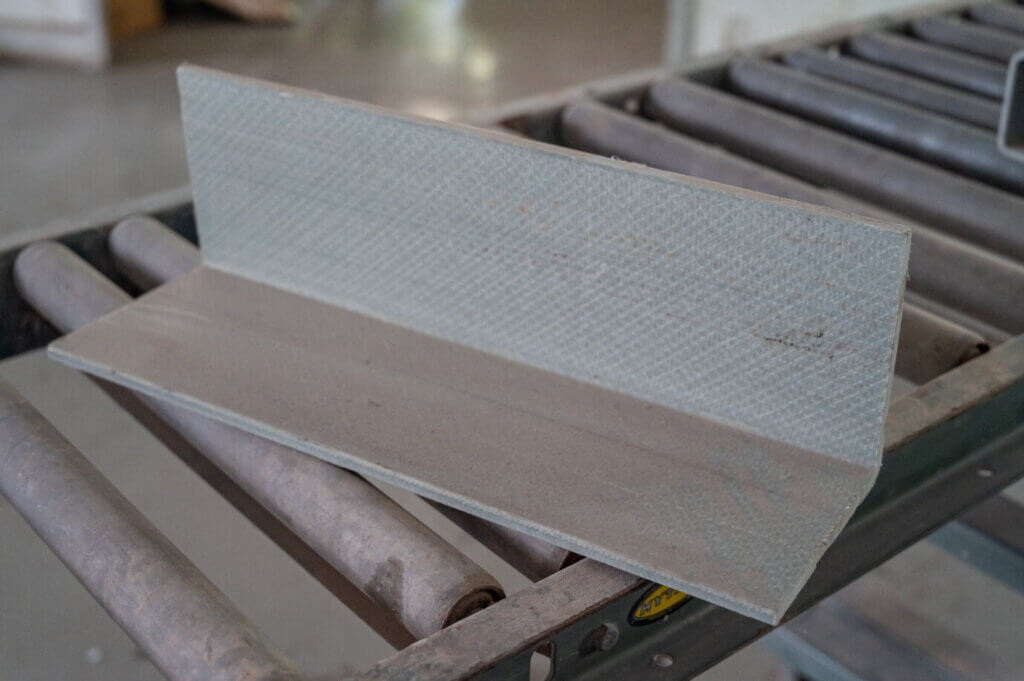

The composites industry is witnessing unprecedented growth, driven by its wide-ranging applications in sectors such as infrastructure, automotive, energy, aerospace, and more. As demand for lightweight and durable materials continues to rise, the need for a skilled workforce capable of leveraging advanced manufacturing techniques like pultrusion has become critical. This specialized training program conducted under the National Technical Textiles Mission (NTTM) and aligned with NSQF standards aims to fill this gap, ensuring that professionals are well-equipped to meet industry standards and contribute to the evolving landscape of composite manufacturing.

The government of India aims to skill on a large scale with speed and high standards in order to achieve its vision of a ‘Skilled India’. At ATIRA we are in complete alignment with this vision and with this skill development program for pultrusion, we playing an active role in realising this vision.

Among the diverse manufacturing techniques for composites, pultrusion stands out due to its ability to produce high-strength, lightweight, and corrosion-resistant components with exceptional precision and consistency. This program is tailored to equip learners with specialized skills in pultrusion, thereby offering access to exciting market opportunities.

Program Highlights:

-

- Classroom Learning: 90 hours of theoretical instruction covering pultrusion operations, quality assurance and workplace safety.

- Practical Training: 210 hours of hands-on experience in resin preparation, machine operations, quality checks and 5S principles.

- Research-Backed Training: Developed with insights from Industries and over seven decades of innovation of ATIRA

- Focus on Advanced Composites: Aligning with India’s growing demand for skilled professionals in technical textiles and composites.

- NSDC approved Certification: Training aligned with NSQF parameters. Gain nationally recognized credentials for better job prospects

- Target Audience: Ideal for aspiring professionals looking to excel in Fiber Reinforced Polymer (FRP) manufacturing and become certified Pultrusion Operators.

Enroll Today:

Be part of India’s Skill Development Mission. Gain the expertise needed to thrive in the booming composites industry.

For registration and more details, contact us at composites-research@atira.in