Composite Materials | Types of Composites | Applications

Introduction of Composite Materials

Composite material is defined as the material formed by combining two or more different materials/ constituents macroscopically that are distinct in the properties and they do not dissolve into each other.

The combination of different constituents in the composites provides the composite material with unique properties which are different from the individual constituent.

An example of composites is the mud building bricks used since ancient times, which is formed by combining mud bricks and straws. This allowed the composite to have the strength and resistance of mud bricks and the tensile strength of straw.

In general, the composite material comprises three main components (a) the matrix, the continuous phase; (b) the reinforcements, the continuous or discontinues phase used to strengthen the composite, and (c) the fine interface region.

For thousands of years, composite materials have played crucial roles in human life, starting with enabling early civilizations to build houses and continuing on to making advances in modern technology possible.

People use composite materials in their day-to-day life, including the ceramic tiling in our bathroom, which help keep us dry.

Composites can indeed be found in the majority of common products, including building and engineering projects, medical applications, energy and transportation, sports, aircraft, automotive, and other fields.

Evolution of Composite Materials

Humans are using composite material for thousands of years. The first composite was found in 1500 BC when mud and straw were used by Egyptians and Mesopotamians to make their houses.

The Mongols developed the first bow using wood, bone, and animal glue. During World War II the civilization of the composite was enhanced and moved from the laboratory into actual production. Also, the development of components from fiber-reinforced polymer composites was adopted by the industries.

By 1945, the use of fiber-reinforced polymer composites started to use primarily in military applications.

In 1946, the first FPR composite boat hull was introduced and by 1947 the automobile body was made from composite material and successfully tested.

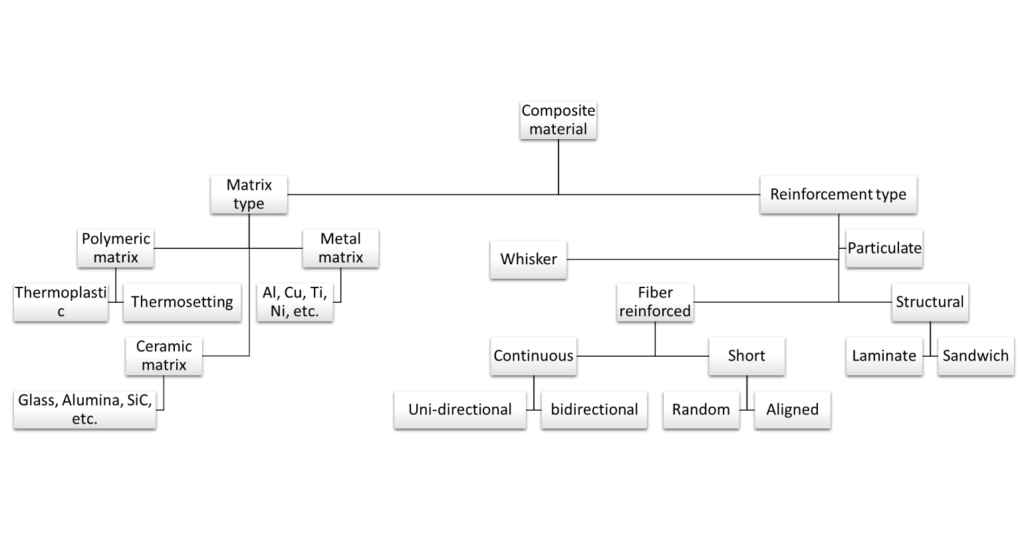

Types of composites

Matrix material

The primary function of the matrix material in polymer composite is to act as a binder and transfer the load between constituents of the composites, provide the component its net shape, and determines its surface quality.

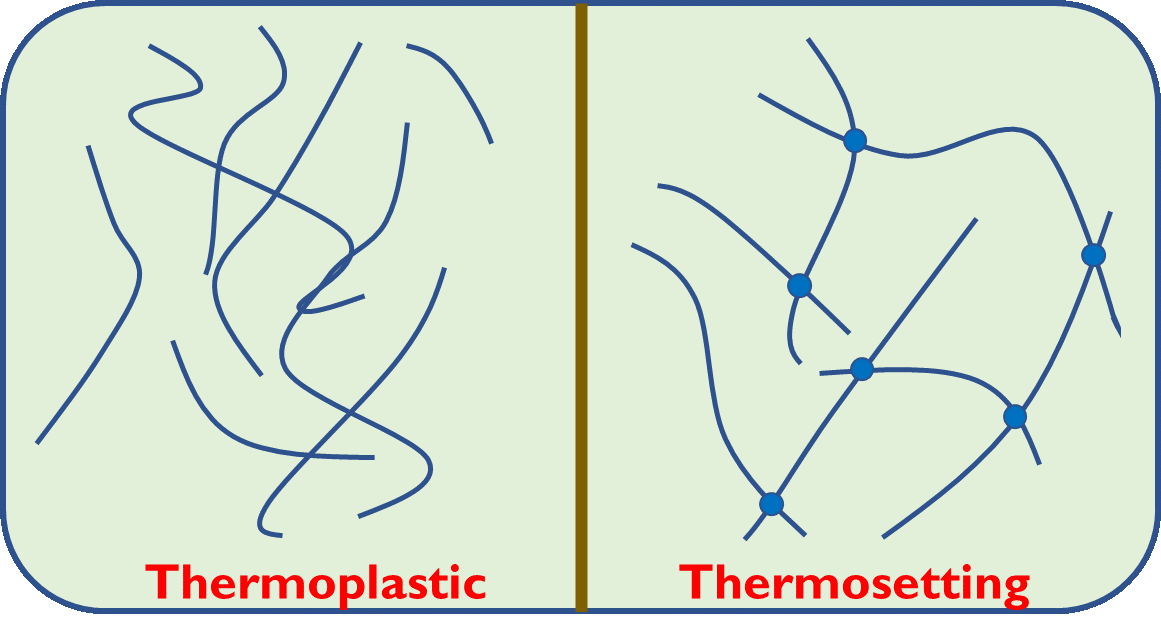

Polymer composites uses generally two types of matrix material viz. thermoplastic and thermosetting. Since the dawn of the composite era, both materials have been used for the development of composites.

The characteristic of the thermoplastic and thermosetting are as follows:

| Thermoplastic | Thermosetting | |

| Introduction | Thermoplastics can be heated and softened and then moulded or shaped and upon cooling it hold the desired shape. It has one- or two-dimensional molecular structure and they tend to show an exaggerated melting point at an elevated temperature. | Thermosetting materials endure an irreversible chemical bond reaction bond i.e., crosslinking or curing during process to change the phase from liquid to solid state. The cross linking enables to eradicates the component remelting with application of heat. |

| Benefits | Can be recycled Remould and reshape capability with the application of heat Easy to manufacture high volumes quickly Chemically retardant and impact resistant Costlier than the thermosets Environment friendly processing adhesive to metal | Cannot be recycled Once cured than cannot be reshaped or remold Better dimensional stability Cost effective More Resistant against high temperature Hard and Rigid Excellent aesthetics finishes Better mechanical properties |

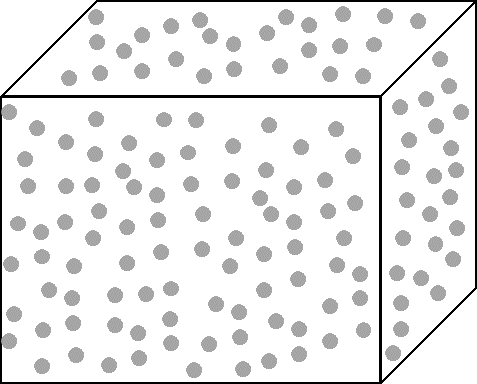

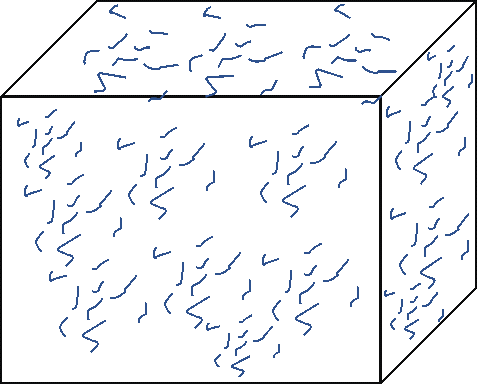

| Structure |  | |

| Types | Some thermoplastic material used in polymer composites: Acrylonitrile Butadiene Styrene (ABS) Poly (methyl methacrylate) (PMMA) (Acrylic) Polybenzimidazole Polyethylene Homopolymer Copolymer Polyurethane Styrene Acrylonitrile Polypropylene (PP)Polyamide (PA)Polycarbonate (PC)Polyether ether ketone (PEEK) Polylactic Acid (PLA) Polyvinyl chloride (PVC) Teflon | Some thermosetting material used in polymer composites: ResinUnsaturated polyesterVinyl esterPhenolSiliconeCyanate estersMethyl Methacrylate (MMA)Bismaleimide (BMI)Urea FormaldehydeFluoropolymersMelamine |

Fiber Reinforcement Composite material

In fiber-reinforced polymer composites, different types of fibers can be used as reinforced material. The selection of the reinforced material is depending on the end application of the component/material. Some common fiber reinforcement is as follows:

Glass fiber

As the name implies the fiber generates from the silica-based or other formulations of the glass by heating at 1675°C. Different types of glass fiber are available based on their properties.

- A-glass (alkali glass): good chemical resistance, but lower electrical properties.

- C-glass (chemical glass): high chemical resistance

- E-glass (electrical glass): excellent insulator and water resistance.

- S-Glass (structural glass): good mechanical properties.

- D-glass (dielectric glass): good electrical properties but poor mechanical properties compared to E & S glass fiber

- E-CR glass fiber (electronic glass fiber): electric resistance, chemical resistance, good mechanical properties, waterproof compared to E-glass

- AR-glass (alkali-resistant glass): specifically used in concrete. It provides strength and flexibility to the concrete in order to prevent the cracks

- M-Glass Fiber: it consists of beryllium in its composition which provides better elasticity compared to E-glass

- Z-Glass Fiber: Used to produce transparent components, high mechanical, UV, acid, alkali, salt, scratch, wear, and temperature resistance, used in 3d printer filament

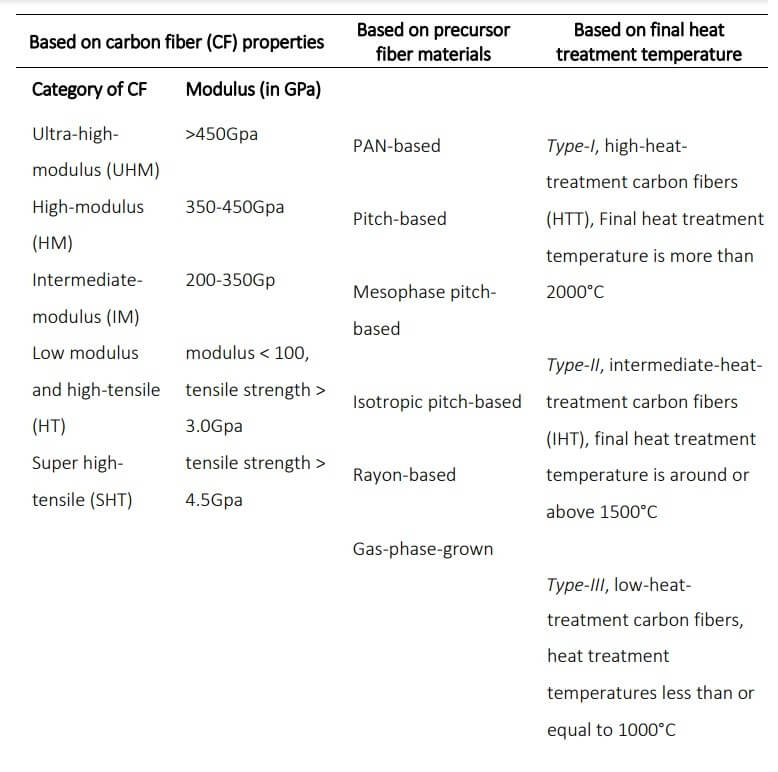

Carbon Fibers

Carbon fiber is composed of carbon atoms bonded together to form a long chain. Carbon fibers are extremely stiff, strong and light compared to glass fiber.

The fibers are extremely stiff, strong, low weight to strength ratio, low coefficient of thermal expansion, and have good resistance to chemical and high temperatures.

Carbon fiber was first invented near Cleveland, Ohio, in 1958.

Based on modulus, strength, and final heat treatment temperature, carbon fibers can be classified into the following categories:

Aramid fibers

Kevlar is made from aromatic polyamide (aramid) fibers, which DuPont made publically available in the early 1970s.

The Kevlar fiber possesses high strength, good resistance to abrasion, chemical resistance, non-conductive, low flammability, and good fabric integrity at elevated temperatures. The aramid fiber generally available in yellow color and widely used in the application where high strength and low weight is required.

Due to its good impact resistance, property Kevlar fiber is used in the ballistic application

Based upon the location of chemical bond in the structure of Kevlar fiber is classified into two types:

- Meta-aramid: The chemical bond of meta-aramid is in a zigzag pattern and the tensile strength of the meta-aramid fiber is lower than the para-aramid. These fibers have good thermal, chemical, and radiation resistance.

- Para-aramid: In para-aramid fiber, the chemical bond structures are aligned in the long direction of the fiber. This type of fiber possesses hood tensile strength. Such fiber is widely used in the civil engineering structural applications

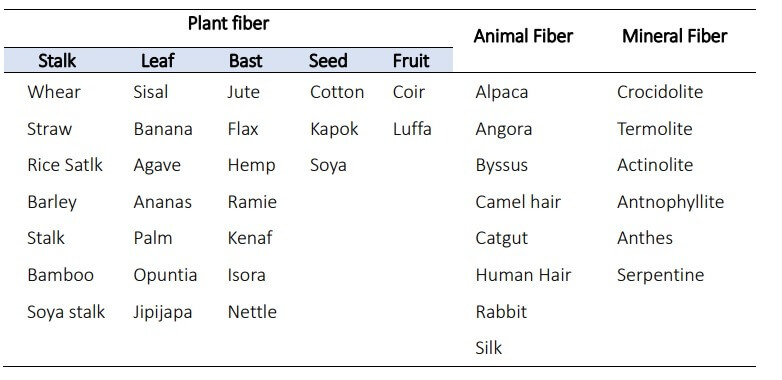

Natural fiber

Natural fiber-reinforced composites have become extremely popular for many uses in recent years, due to their good characteristics.

Due to government policies and environmental consciousness the use of natural fiber in polymer composite increases.

Natural fibers have low density, high specific strength and provide good thermal and acoustical insulation. The natural fiber is derived either from plants or animals.

These fibers have an edge over synthetic fibers in various sectors such as automobile, construction, and sports industries because of their comparable mechanical properties with glass fiber.

Classification of Natural fiber

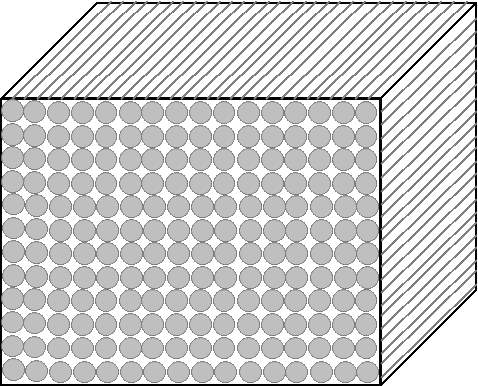

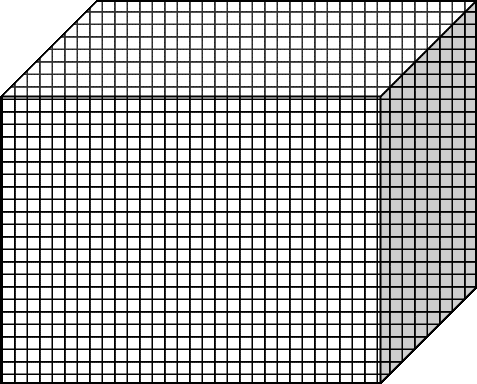

Classification based on reinforcement structure

|  |

| Particle reinforced | Short fiber reinforced |

|  |

| Unidirectional fiber reinforced | Bidirectional reinforced |

| |

| Laminate composite |

Applications of Composite Materials

- Space: antenna, radar, satellite structures, solar reflectors, etc.

- Aircraft: aerofoil surfaces, compressor blades, engine bay doors, fan blades, rotor shafts in helicopters, turbine blades, turbine shafts, wing box structures, etc.

- Automobiles: automobile body, bumper, mudguards, door panels, dashboard, driveshaft, fuel tank, CNG cylinder, chassis, fender, etc.

- Wind turbine blades: rotor blades, nose cone, nacelle cover, accessories for wind electric generators.

- Sports: Skis, surfboards, windsurfing, table tennis boards, slats, and gliding wing spar, Tennis, badminton, fishing rods, golf clubs, baseball bats, hockey sticks, pole shaft, Sword, etc.

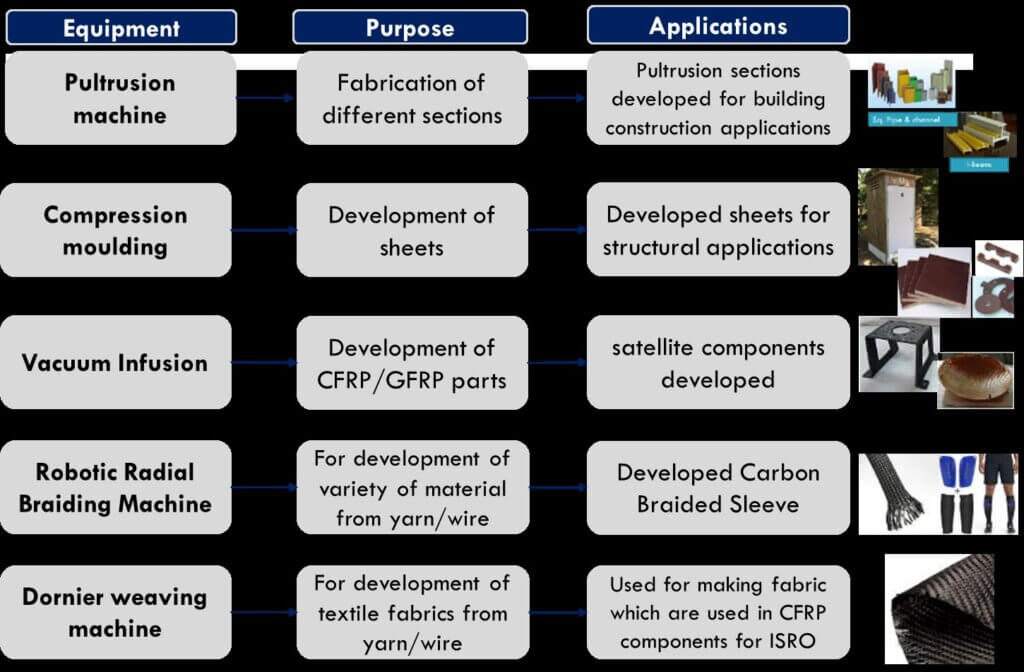

Centre of Excellence – Composites at ATIRA

ATIRA was declared as “Centre of Excellence in Composites” by the Ministry of Textiles, Government of India in March 2011.

ATIRA has created a Centre of Excellence (CoE) for developing advanced composites applications through an advanced process in order to achieve weight reduction, high mechanical properties, cost competitiveness and to enhance the knowledge base in composites through research, development, and training.

Work done at ATIRA (Composite Materials)

- Carbon Fibre and Epoxy Resin-based products through vacuum infusion process. Various components for satellite communication systems have been developed. These works have been done for SAC-ISRO Ahmedabad.

- Satellite communication systems were also developed using carbon-epoxy prepregs.

- The carbon core material is under development for making homogeneous sandwich panels for better performance.

- Natural fibers like jute and cotton-based composites were developed using the compression molding process. These find application in partition, door, and engineering fabrication.

- Pultrusion based composite profiles developed for diversified applications like building construction, furniture, cooling tower, etc.

- Compression-molded composites that are based on synthetic reinforcement like Glass fiber, Carbon fiber, Aramid, etc, and natural reinforcement like Cotton fiber, Jute fiber, etc have been developed for diversified applications.

- Vacuum infusion (VARI) based process used to developed space and aircraft products based on carbon, aramid, and epoxy system. Also, sandwich structure based on an aluminum honeycomb, carbon core and quartz core, etc. also developed.

Fabrication & processing facilities available at ATIRA

If you are interested to get more information, please write to composites-research@atira.in

References:

- Ngo TD. Introduction to composite materials. Composite and Nanocomposite Materials From Knowledge to Industrial Applications. 2020 Feb 25.

- Dawoud MM, Saleh HM. Introductory chapter: Background on composite materials. characterizations of Some Composite Materials 2018 Nov 5. IntechOpen.

- Priyanka P, Dixit A, Mali HS. High-Strength Hybrid Textile Composites with Carbon, Kevlar, and E-Glass Fibers for Impact-Resistant Structures. A Review. Mechanics of Composite Materials. 2017 Nov;53(5):685-704.

- Bhatt P, Goe A. Carbon fibres: production, properties and potential use. Material Science Research India. 2017 Jun 25;14(1):52-7.

- Ashik KP, Sharma RS. A review on mechanical properties of natural fiber reinforced hybrid polymer composites. Journal of minerals and materials characterization and engineering. 2015;3(05):420.

- Saba N, Jawaid M. Epoxy resin based hybrid polymer composites. InHybrid polymer composite materials 2017 Jan 1 (pp. 57-82). Woodhead Publishing.

- Rajak DK, Pagar DD, Menezes PL, Linul E. Fiber-reinforced polymer composites: Manufacturing, properties, and applications. Polymers. 2019 Oct;11(10):1667.

- Zhang L. The application of composite fiber materials in sports equipment. In2015 International Conference on Education, Management, Information and Medicine 2015 Apr (pp. 450-453). Atlantis Press.

- https://www.addcomposites.com/post/reinforcement-fibers-terminology-types-and-formats

- https://www.homestratosphere.com/types-of-fiberglass/#6ECRGlassFiber