Case Study (Fabric Defect Analysis)

Case study of modal microfilament knitts with cotton contamination during splicing (Fabric Defect Analysis)

CUSTOMER REQUEST:- Pink dyed knitted fabric of 42s Ne 100% micro modal + SPANDEX submitted for short lines defect analysis.

Investigation of yarn contamination in Modal Spandex Single Jersey knitted Dyed fabric

We have applied the scientific way in four stages to investigate the problem because such defect is difficult to quantify directly or indirectly by any specific tests in the laboratory. SEM images can provide help to recognise the physical form of the fibres and we can create inferences to support our investigation. FTIR data may not be that much suitable as both natural and regenerated fibres belong to the same polymer class. So we performed qualitative tests only to validate our hypothesis in correlating the fibre characteristics. Unravelled yarn shows the distinct optical difference in magnified images & that’s why we decided against stripping & redyeing rejecting out rightly basic preparation fault.

Through visual observation of the fabric under transmitted light and overhead light.

The yarn contamination was typical in nature & shows a singular short line along the course way with sharpness having equal dimensions to adjoining micro modal yarn diameter. Refer to the two images given below for understanding. It was difficult to conclude very easily with tangible data. We adopted methodology step by step to conclude the final cause & identification the defects as the contamination/foreign yarn presence.

Forming the hypothesis in respect to defect and its cause.

From the defective yarn portion, the laboratory analyst unravelled yarn for further studies of individual fibre characteristics. There was a substantial difference in depth of the colour in both yarns.

Two different constituents of fibres led analysts to believe the possibility of the cause as foreign contamination. Analysts gathered that the typical contamination of yarn was of 100% cotton mixed at the splicing stage. The lighter joint place in yarn clearly distinguished at either end suggested foreign fibres presence as contaminated yarn. Further to establish the hypothesis analyst carried more observations.

Lab test is done to support hypothesis/assumption to validate scientific facts or truth.

Modal fibres possess higher absorbency than cellulosic fibres but a lesser degree of absorbency than viscose. Though it belongs to the manmade – natural fibres category, referred to as semi-synthetic fibre also. The degree of polymerisation of Modal is around 1000 compared to 1800 of Cotton, 400-600 of viscose. It is more crystalline in structure and fibres are complete circular in shape. The moisture regain is around 11.5%. It is referred to as HWM fibre (-high wet modulus) due to the higher value of tenacity.

The behaviour of dyeing to support the investigative principle of qualitative nature.

Since Modal like viscose fibre always dyes at a higher depth of 5 to 10% on an average than cotton, when dyed exhibits a higher depth than cellulosic. The distinct difference in shade depth was evident in unravelled individual yarn in the natural light also.

Contamination issue was primarily to be judged with fibre identification test by shape & geometry through microscopic observations. The observations reveal the below data:

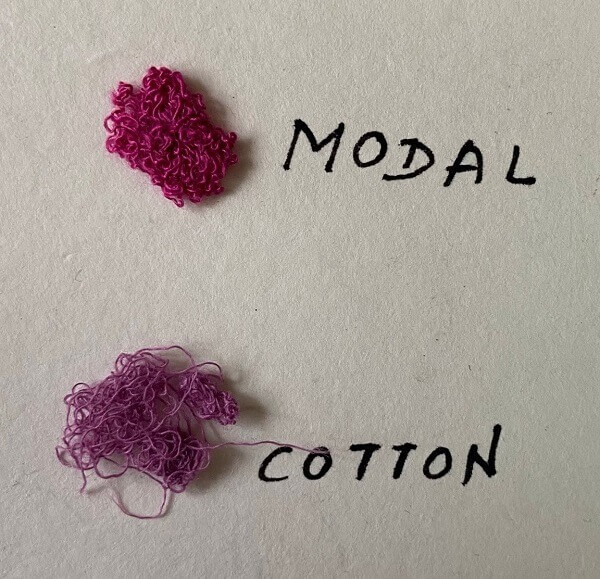

- The unravelling of darker and lighter parts into two different coloured yarns shows one deeper fibre /yarn shiny & silky and with brilliance.

- Other yarn is duller and lighter in depth. The microscopic observation showed modal microfiber in a perfect cylindrical shape very similar to the polyester type and cotton lighter dyed fibre shows convolutions with a natural ribbon-like structure.

- Both the fibres were subjected to fibre identification qualitative analysis test under 70-75 % sulphuric acid, density 1.665 and temp of 750 F, within few minutes they dissolved easily. That confirmed natural cellulose fibre presence as contamination in 100% modal viscose microfibers fabric. The spandex part remains unaffected.

- The presence of any other popular synthetic fibres like polyester/polypropylene and polyamide was denied through this test.

End findings: –

The photographs attached clearly show a separate yarn of cotton has merged into modal yarn at the time of splicing and here both the images confirm face with straight-line /back two parallel lines with inter looping having equal stitch length.

Extra cotton yarn with similar dimensions introduced during spinning shows the sharp difference in colour uptake due to differential dye pick up/dyeability factor and shows as a straight line as a defect.